Appropriate safety foot wear worn by employees reduces risk to injuries. Protecting employees’ feet with quality safety boots improves productivity, boosts their morale as well as cuts lost work hours.

Protective foot wear is required by workers in industrial settings, as the federal regulations adopted and enforced by the Occupational Safety & Health Administration (OSHA) states.

Foot wear is included in the category of Personal Protective Equipment’s in the section of the Occupational Safety and Health Standards. It majorly focuses on the employers who deal in industrial, construction as well as government and service fields.

OSHA suggests that footwear protection should be worn by employees who are likely to work in the following conditions;

- Electrical hazards

- Heavy objects that could fall and injure employees feet

- Molten metal that is likely to splash on the workers feet

- Sharp objects that poses a risk to puncture worker’s feet

- Corrosive or poisonous material

TIPS BEFORE PURCHASING A QUALITY SAFETY WEAR

Since safety boots are made of different material, designs, as well as materials, one has to do research before purchasing them for the first time.

Below are important things that a first buyer should consider before purchasing one.

SOLES

Because different workers are exposed to different work hazards, one should consider purchasing the right kind of safety wear since they are made of different materials, designs as well as styles.

Employers who work in conditions that expose them to chemicals or oil, they are supposed to purchase safety boots that their outsoles are made from Thermo-Poly Urethane. This material is lightweight, tough and it can even resist splitting.

Also, workers who spend most of their time working on slippery floors, should consider purchasing a safety boot that is anti-slip in order to prevent potential risks of falling, which can lead to broken bones, as well as preventing head injuries.

If workers spend most of their time in rugged terrains, they should consider purchasing safety shoes that have rubber soles. This sole is as well preferred by workers in the construction and manufacturing sites.

RIGHT FIT

Aside from material used in making these safety boots, one should consider wearing safety foot wear that best fits their feet. Too big or too small safety boot could affect workers’ comfort more so affecting their productivity.

Read Also: Top Reasons you should wear a safety boot

Too small safety shoes could lead to blisters, bunions, corns and calluses, which causes discomfort to the workers at the end of the day. Comfort is the key thing in order to provide efficiency to workers.

Toe box needs to be deep enough so that one can move all their toes inside without feeling any pressure.

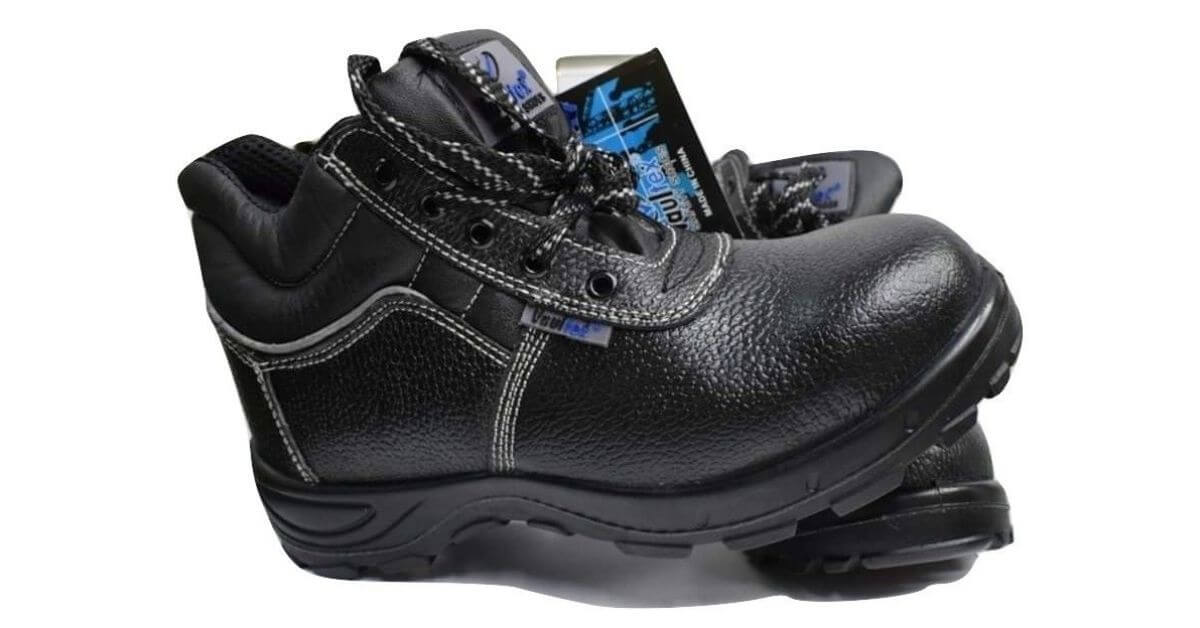

STYLE

Safety shoes come in different styles, in terms of material, designs, as well as colors. For example;

Vaultex Safety Boots; They are slip-proof, steel toe, unisex, genuine leather, oil resistant, anti-static, waterproof and has extra padding for ankle support

They are unisex boots, oil and chemical resistant, steel toe, steel plate, split embossed leather, shock absorbent, and dual density sole.

They are anti-slip, unisex, shock absorbent, oil resistant, petrol and chemical resistant and has a steel midsole

They are construction safety, has genuine leather, unisex, steel toe, slip proof, water proof, shock absorbent and has a light weight.

WHEN SHOULD ONE REPLACE THEIR SAFETY SHOES?

- Dented toe

Think safety when the steel toe has a dent since it will not spring back. This will cause discomfort. One is supposed to be cautious when their safety boots are tasted by major impacts or punctures.

- Worn out sole

Attention should be paid to the safety shoes wear when their sole has been worn smooth. This will no longer serve their key function of being slip resistant.

- Leakage

Any sign of leakage should prompt the worker to purchase new pair of shoes. This is very critical especially when employees are exposed to the environment that may lead to exposure to hazardous chemicals or corrosive material.

- Wear and tear

As soon as the protective component has started to show through be it steel midsole, steel midsole or metatarsal guard, one should replace their boots immediately.

CONCLUSION

Workplace accidents that results from inappropriate footwear protection can put an individual out of work and can lead to costly expenses to both the injured worker as well as the employer.

Without the proper foot protection, it dramatically increases the chance of a worker being injured. This is why choosing the right footwear is so important.

Read Also: Top reasons you should wear a safety Overall

We Safety Hub Enterprises, we deal with quality safety boots, that meets health and safety regulations standards, that meet category EN ISO 20345. Your safety is our concern!

As the leading PPE’s and uniforms supplier, we are proud to be able to offer some of the highest quality workplace safety equipment and uniforms in Kenya. Such include; school uniforms, overalls, dust coats, safety boots, spray suits, medical scrubs etc